| Energy Saving Jet Mill | ||||||||||||||||||||||||||||||||||||||||||

+ Fluidized Bed Classifying Jet Mill + Precision Air Classifier + Classifying Impact Mill + Abrasive Powder Classifying Jet Mill/ Shaping + Bag Collector + Ultrafine Powder Processing Line

|

|

|||||||||||||||||||||||||||||||||||||||||

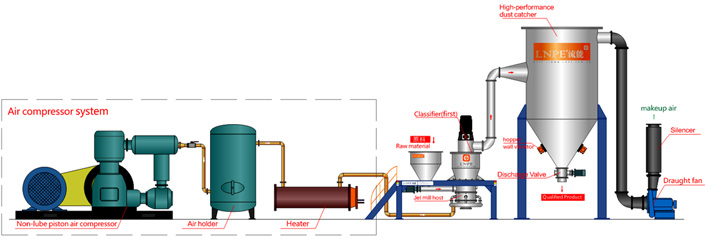

| Energy-saving Jet Mill is a newly developed grinding equipment based on the fluid energy conversion character in adiabatic flow process. It makes the most of fluid pressure and internal energy to grind material with a high efficient and saves about 30% energy than other ordinary grinding equipment. 1.High energy utilization ◆The air compressor used for ordinary jet mills prevent operation fault caused by high exhaust temperature. A higher pressure is got through intercooling for multistage compression,the more stages it is, the lower the energy utilization rate is, for instance,the energy utilization in the primary compression is 78% and 58% when it`s in secondary compressor. ◆Energy-saving Jet Mill adopts Primary high exhaust temperature compressed gas to grind material and the grinding force is the same with secondary compressor. Using the energy of air temperature prevents energy loss in cold and heat offset during intercooling in compressor. 2.Helpful in material grinding Materials with joints and fissures weak effect plane such as :Talc, wollastonite, etc, are easily ground due to thermal expansion effect. 3.Materials are dried after warming. |

||||||||||||||||||||||||||||||||||||||||||

| ■Application field | ||||||||||||||||||||||||||||||||||||||||||

| ■Main technical parameter | ||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||